Applications

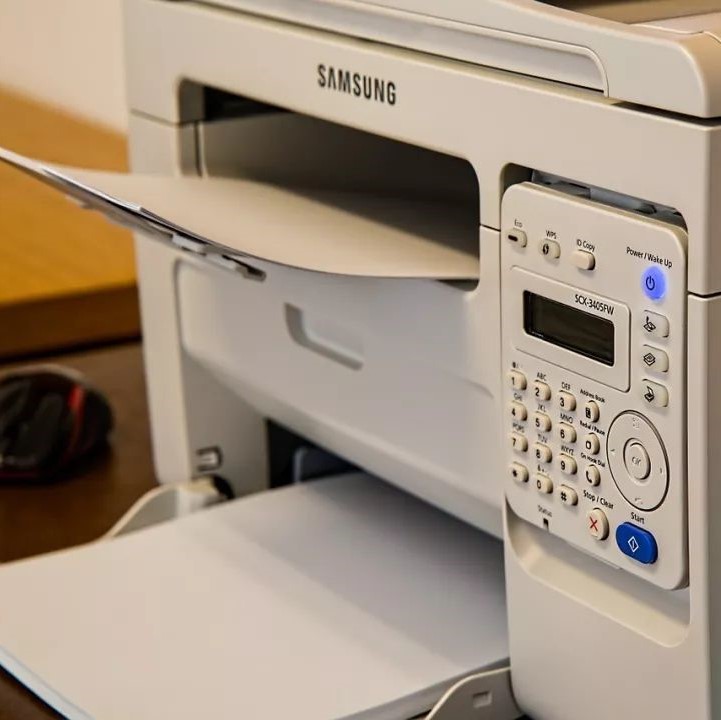

Being an authentic silicone manufacturer, we have marked a noticeable position in the industry. With the help of sophisticated technology and experience (accurate control microcellular foam technology), we are able to provide superior silicone foam roller (high precision dimension and quality) for our customers. We gather all our efforts in every single roller for copier, multi-functioned printer, and printer. We provide you not only standard but also bespoke silicone foam rollers. Welcome to contact our product manager to discuss your individual requirements.

![]() ILLUMINATE A BEAUTIFUL LIFE

ILLUMINATE A BEAUTIFUL LIFE

Trancy

Started in 1974, Trancy is a leader in silicone and solutions, committed to exploring and developing the applications of silicone materials. With more than 40 years of silicone R&D and manufacturing experience, Trancy provides more than 2000 silicone products and is able to produce tailor-made products based on your special demands.

Trancy Personal Care Business Unit

Trancy personal care R&D center specializes in researching, developing and testing new silicone products for personal care and improving their performance. Our newest silicone technologies are available for the formulation of innovative skin care products.

Trancy has developed cyclic, linear, or organo-functional polydimethylsiloxane, silicone elastomer and resins, delivering superior aesthetics and unmatched, cost-effective, sensory benefits for the formulator with endless possibilities.

Product Manager :

Mr.Yu +86 177 2766 2733

winson.yu@trancytech.com

Whatsapp: +86 177 2766 2733

Inquiry Form