Applications

- Adhesion and seal to lamps such as energy-saving lights, automobile lights and panel light, etc.

- Unprimed adhesion to commonly used materials including glass, aluminum, and engineering plastics, e.g. induction cooker, household appliances, kitchen ventilator.

- Various adhesive and seal application in other industries.

- Designed for applications which demand a strong but flexible bond, such as when bonding materials with different thermal expansion rates, e.g. adhesion of glass to metal or glass to plastic.

How to Use Silicoen Adhesive Sealant

- CX-3391 silicone adhesive sealant should be used over a temperature of 4°C to 40°C and relative humidity of 40% to 80%.

- All surfaces must be clean and dry. Degrease and wash off any contaminants that could impair adhesion. Suitable solvents include isopropyl alcohol, acetone or methyl ethyl ketone.

- Apply CX-3391 silicone adhesive sealant to one of the prepared surfaces, then quickly cover with the other substrate to be bonded.

- On exposure to moisture, the freshly applied material will “skin-over” in about 10–15 minutes at room temperature and 50% relative humidity. Any tooling should be completed before this skin forms. The surface is easily tooled with a spatula.

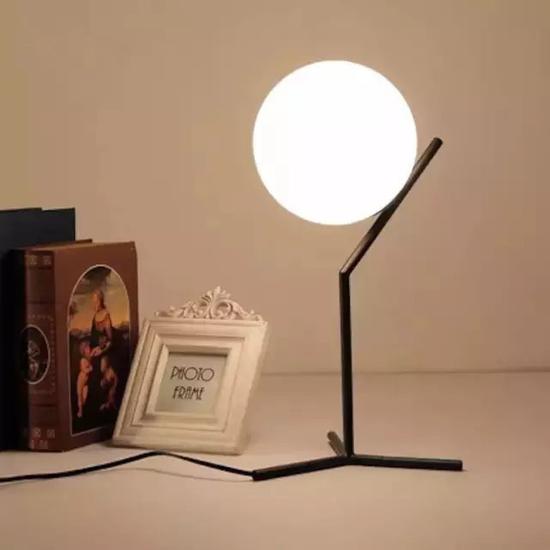

![]() ILLUMINATE A BEAUTIFUL LIFE

ILLUMINATE A BEAUTIFUL LIFE

Trancy

Started in 1974, Trancy is a leader in silicone and solutions, committed to exploring and developing the applications of silicone materials. With more than 40 years of silicone R&D and manufacturing experience, Trancy provides more than 2000 silicone products and is able to produce tailor-made products based on your special demands.

Trancy Personal Care Business Unit

Trancy personal care R&D center specializes in researching, developing and testing new silicone products for personal care and improving their performance. Our newest silicone technologies are available for the formulation of innovative skin care products.

Trancy has developed cyclic, linear, or organo-functional polydimethylsiloxane, silicone elastomer and resins, delivering superior aesthetics and unmatched, cost-effective, sensory benefits for the formulator with endless possibilities.

Product Manager :

Mr.Yu +86 177 2766 2733

winson.yu@trancytech.com

Whatsapp: +86 177 2766 2733

Inquiry Form